Day in the life of

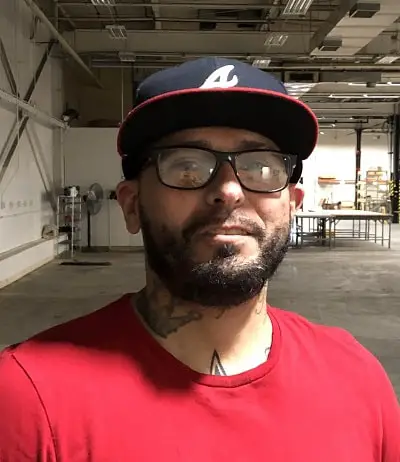

Metal Fabricator – Rico Algarin

A typical day starts off with turning on all the light and power to needed machines, then into the office to make coffee and have the morning meeting, going over what’s on the agenda for the day. Then I’ll head to my metal area, where I could either continue on with a project or set up for the next. I’ll begin by reviewing drawings and plans, allocating my materials, and breaking out the tools I’ll need. Then I’ll pop in my headphones and get to work.

Sometimes problems pop up and then I have to figure out how to fix it with what we have, and that’s where it gets interesting. I would also help out in other departments as needed, which includes tasks from painting, carpentry, and logistics of the shop.

Some of my responsibilities include making sure tools and heavy machinery are being used properly, making sure all supplies and consumables are stocked or ordered. As I am usually the last to leave, I’ll make sure the machines are turned off and power down the shop. I make sure the shop is locked properly and is clean ready for the next day.

One of Rico’s work, a metal rose

Pros

I’m making something cool and different every project. I enjoy the fact that there’s always a problem or puzzle to solve in order to bring the work to fruition. I work with some of the best people in the industry let alone in the same shop. Most of the people I work with I can consider friends, and it makes communication so much more effortless at times. Every project is unique so it’s awesome to have that variety of the workplace.

Cons

I wish we had more “toys” to work with! As anyone in a shop wants.

Structural Metal Fabricators and Fitters

fabricate, position, align, and fit parts of structural metal products.

.jpg)